Light-Emitting Diodes (LEDs)

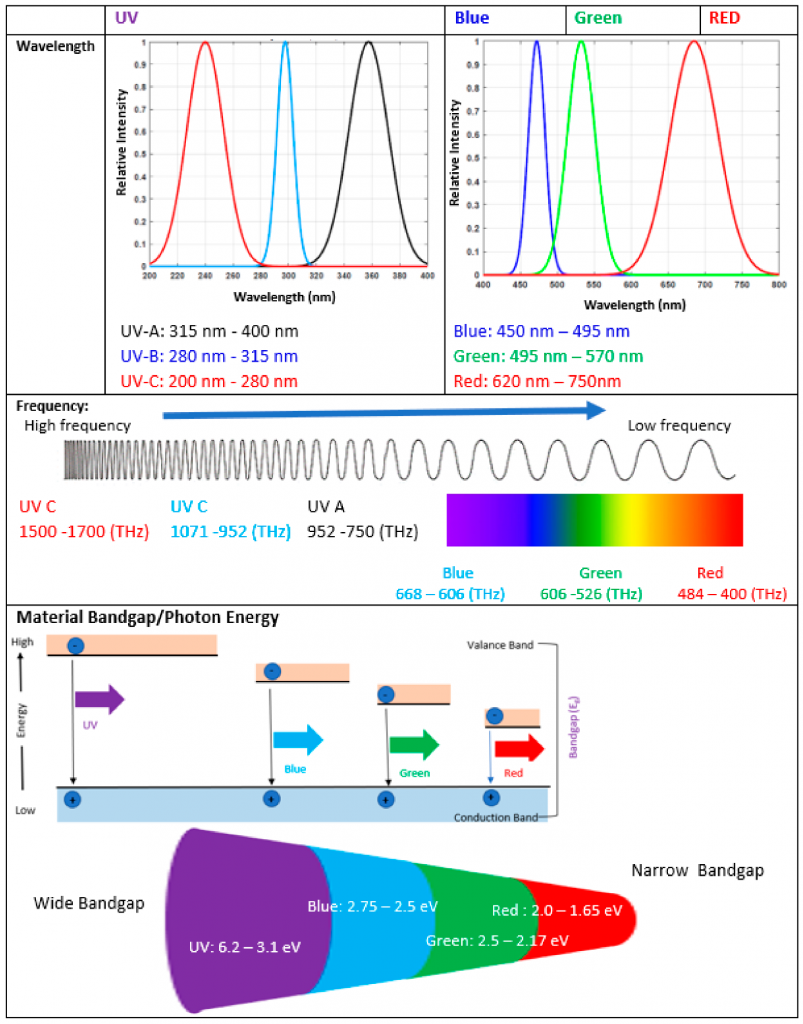

The foundation of light-emitting diodes (LEDs) was laid by Russian physicist Oleg Vladimirovich Losev at the beginning of the 20th century. In 1927, Losev received the first patent for a prototype light-emitting diode. In the 1960s, American scientist Nick Holonyak produced red LEDs. Following the development of red LED technology and techniques, orange, yellow, and green LEDs were introduced to the market. In the late 1980s and early 1990s, Japanese researchers Isamu Akasaki, Hiroshi Amano, and Shuji Nakamura made a breakthrough with the development of blue LEDs based on GaN (gallium nitride). Akasaki and Amano improved the crystallinity of the material by developing epitaxial growth techniques for GaN crystals. Nakamura succeeded in producing higher-efficiency blue LEDs using indium gallium nitride (InGaN). These studies were honored with the Nobel Prize in Physics in 2014. In 1993, the first commercial blue LED was introduced by Nichia Corporation. Blue LEDs, combined with phosphor coatings, led to the development of energy-efficient LED lamps that produced white light. This revolutionized the lighting industry, replacing traditional incandescent bulbs. Ultraviolet (UV) LEDs developed rapidly in the 2000s. Researchers such as Akasaki and Hirayama increased the efficiency of deep UV LEDs using AlGaN-based materials. In 2009, devices with high efficiency at UV-C wavelengths were developed. UV LEDs are now being used in water purification, surface sterilization, and biomedical applications. Figure 1 shows the wavelength, frequency, and bandgap of UV, blue, green, and red light.

Figure 1. Wavelength, frequency, and bandgap of UV, blue, green, and red light [1]

LED Operating Principle

The operating principle of LEDs is based on the p-n junction. By using a semiconductor material with a direct bandgap, electrons are allowed to emit photons (light) as they transition from a high-energy state to a low-energy state. Depending on the energy bandgap, the emitted light can range in wavelength from UV to infrared. Table 1 shows the growth method, material combination, and p-n junctions required for UV, blue, green, and red-light emission reported in the literature.

Table 1. Growth method, material combination, and p-n junctions used for UV, blue, green, and red-light emission [1]

| Category | UV | Blue | Green | Red |

| Growth Method |

|

|

|

|

| Group Combination

(III, IV, VI) |

|

|

|

|

| Junction Types Used in Production |

|

|

|

|

Various growth methods are used to achieve better, optimal performance in LED production, as shown in Table 1. MOCVD is widely used for LED growth by providing device-matching conditions. MOCVD is used to achieve different emission wavelengths in the growth of GaN-based LED structures on various substrates, including sapphire and silicon. MBE is known for its ability to produce high-quality epitaxial layers of ZnO layers. LPE is another method used in LED production and offers the opportunity for the growth of multilayer structures such as InAs/InAsPSb/InAs/InAsPSb. Advances such as MOCVD and HVPE are widely used to produce high-quality semiconductor films and nanostructures. In summary, the choice of LED growth method is crucial in determining the device’s appearance and properties. The technique used, such as MOCVD, MBE, or LPE, offers distinct advantages in tailoring LEDs to specific applications.

Applications of Ultraviolet and Blue Light-Emitting Diodes

Agricultural Use

It has been widely researched that LED lighting can significantly increase plant productivity. The intensity, duration, and spectral characteristics of lighting are critical factors in determining the extent and character of plant growth and development. LED lighting, with its diverse spectrum of light, such as UV-A and blue light, can influence the biosynthesis of phytochemicals and enhance plant development during the growth, elongation, branching, flowering, and seedling stages. This technology offers an environmentally friendly and energy-efficient alternative to traditional methods, optimizing plant growth while contributing to the reduction of chemical pesticide use. Thanks to the controlled spectral characteristics of LEDs, targeted lighting strategies are being developed to support plant defense mechanisms in agricultural and greenhouse applications.

Figure 2. UV-LED and Blue Light Applications in Agriculture

Produced or processed foods are often subject to natural spoilage and contamination by microorganisms. This occurs throughout the food supply chain, resulting in high levels of food waste and compromising consumer safety. Light-emitting diode technologies, a new non-thermal surface disinfection method, can be used to reduce microbial activity and improve product shelf life. Foods are often stored or processed with heat, freezing, chemical preservatives, modified atmosphere packaging, and edible coatings. These processes can reduce quality due to chemical and physical changes. UV-light is a non-thermal technology used as an alternative to these methods.

Figure 3. Extending the Shelf Life of Foods with UV-LEDs

Water Treatment

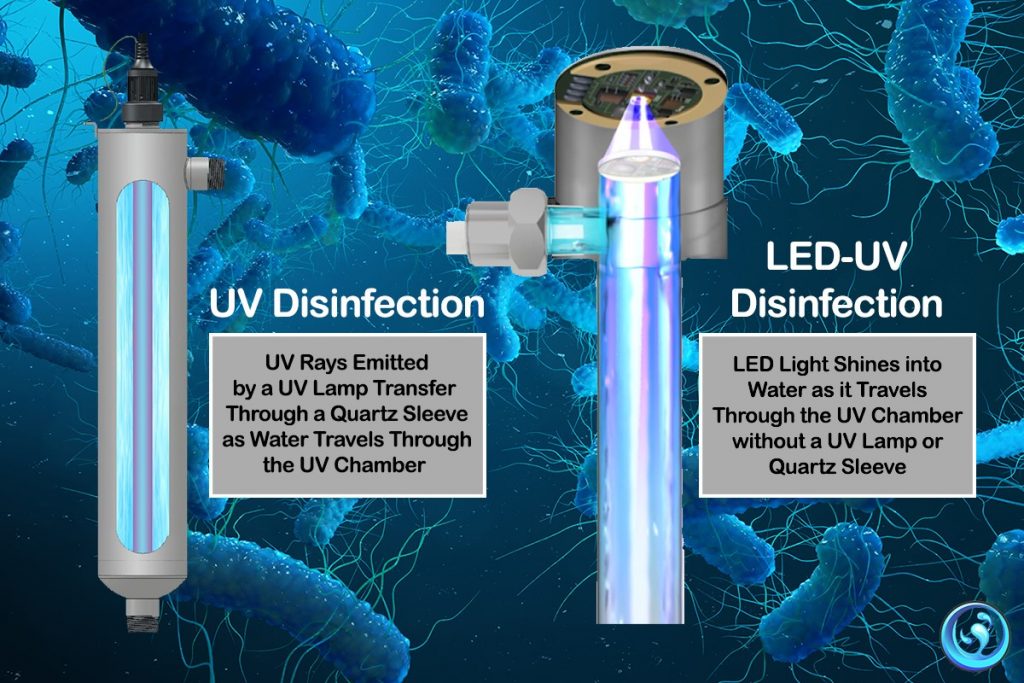

UV LEDs have unique properties compared to other traditional UV sources. There is a high demand for improved disinfection applications, particularly for use in water treatment and microbial disinfection. UV LEDs can be highly effective in inactivating chlorine-resistant pathogens that produce negligible byproducts. They can be easily retrofitted into existing treatment units. Prototype water treatment and sterilization systems based on UV LEDs have been demonstrated using wavelengths ranging from 210 to 365 nm. Numerous studies have investigated the effectiveness of different wavelengths in inactivating bacteriophages, bacteria, and viruses. A significant study by Cheveremont et al. highlighted the strong microbial reduction achieved by combining UV-A and UV-C in wastewater treatment. Furthermore, certain combinations of 280/365 and 280/405 nm have proven highly effective in significantly reducing mesophilic bacteria.

It was concluded that UV-LEDs would be a better alternative for water treatment and pathogen inactivation compared to traditional disinfectants and other UV sources. Because UV-LEDs do not contain mercury, they are free of toxicity issues. Their robust and compact design makes them more durable and relatively easier to use. There is significant potential to improve the efficiency, cost, and lifespan of UV LEDs for future applications in various fields.

Figure 4. Use of UV-LEDs in Water Treatment [2]

UV LEDs in Microbial Disinfection

UV-C light is a highly effective method for inactivating microorganisms. This process works by damaging the genetic material and protein structures of microbes. For example, UV light causes damage to a type of protein called thymine dimer in the DNA or RNA of viruses and bacteria. This prevents the genetic material from replicating and inactivates microorganisms. At the same time, UV light damages proteins, causing cells to lose their functions. These processes create an environment in which microbes cannot survive.

UV-C light, particularly in the 207-222 nm range, is both powerful enough to kill microbes and safe enough not to harm human tissues such as skin and eyes. This feature makes the use of UV-C LEDs both effective and safe in disinfection applications.

Figure 5. Use of UV LEDs in microbial disinfection [3]

Advantages of Blue and UV LEDs

- High Energy Efficiency

- Compared to traditional disinfection methods, energy consumption is quite low.

- Provides long-lasting use with low power consumption.

- Environmentally Friendly and No Chemical Requirement

- Disinfect surfaces and the air without the need for chemical disinfectants.

- Environmentally hazardous waste production is minimal.

- Broad-Spectrum Antimicrobial Activity

- It is effective against both bacteria and viruses.

- It is a promising technology for inactivating viruses such as SARS-CoV-2.

- Safe Use

- 207-222 nm UV-C light can inactivate microbes without harming human skin and eyes.

- It is both effective and safe when used at the correct wavelengths.

- Portability and Flexibility

- Its compact design makes it easy to use in various areas.

- It is ideal for portable devices.

- Long Lifespan and Low Maintenance Costs

- Compared to traditional bulbs, LEDs have a much longer lifespan.

- They do not require replacement parts or frequent maintenance.

- Suitable for the Food and Healthcare Sectors

- Blue LEDs preserve the nutritional value of food and extend its shelf life.

- UV LEDs are an effective tool for sterilizing medical devices and surfaces.

- Rapid Disinfection Process

- They provide effective sterilization in a short time, making them especially useful in situations requiring rapid results.

- Low Heat Generation

- They generate minimal heat during operation, increasing energy savings and making them safe for use on a variety of surfaces.

These features make blue, and UV LEDs preferred in many areas, including healthcare, food, water treatment, and industrial applications

CUNAM’s Projects

We are making significant contributions to the field of semiconductor lighting technologies by focusing on our innovative work. In line with today’s expanding application areas and new technological developments, the design, production, and characterization of high-efficiency LED structures are of great strategic importance. In this context, we conducted studies on advanced LED technologies with the project numbered 113G103, “Development of LED Chip Prototypes,” under the TUBITAK 1007 grant. High-energy-efficient solutions for smart displays were developed with the project numbered 115-E-109, “Design, Production, and Characterization of High-Efficiency LEDs for Backlighting in Smart Displays,” under the TUBITAK 1003 grant. Additionally, the growth and device characterization of LED structures were carried out under CUBAP projects F-488, “Growth and Structural Characterization of a Blue LED Structure on a Sapphire Substrate by MOCVD,” and under CUBAP projects F-493, “Electrical Characterization of a Blue LED Structure Grown on a Sapphire Substrate by MOCVD.” These projects have provided significant knowledge on the development and industrial integration of high-performance LEDs.

References

[1] Bhattarai, T., Ebong, A., & Raja, M. Y. A. (2024, May). A Review of Light-Emitting Diodes and Ultraviolet Light-Emitting Diodes and Their Applications. In Photonics (Vol. 11, No. 6, p. 491). MDPI

[2] https://www.wahlwater.com/UV-vs-UV-LED-Systems–Comparison_b_52.html